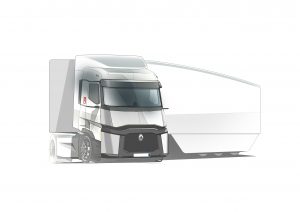

Renault introduces the Falcon project in which it develops a complete heavy goods combination to demonstrate an ambitious potential to reduce fuel consumption and CO2 emissions through innovative design.

Renault introduces the Falcon project in which it develops a complete heavy goods combination to demonstrate an ambitious potential to reduce fuel consumption and CO2 emissions through innovative design.

Lower fuel consumption is ofcourse at the core of the development of Renault Trucks vehicles, which are designed to be profit centres for transporters. In line with Optifuel Lab 1 and Optifuel Lab 2, and more recently the Urban Lab 2 project involving distribution vehicles, Renault Trucks is now undertaking the development of a new experimental combination designed to consume 13% less fuel than a standard coupling towed by a Renault Trucks T.

The FALCON (Flexible & Aerodynamic Truck for Low CONsumption) project is led by Renault Trucks with a consortium of partners. The technical developments are aiming to achieve a maximum client ROI of two years in normal operating conditions, with a view to starting production in the medium term. Developments are focusing on the optimised aerodynamics of the truck and trailer combination, connected low rolling resistance tyres and predictive energy-saving driving aid and fuel management functions, together with an improved powertrain using a new-generation Rankine heat recovery system and optimised lubricant formulations. With the exception of the Rankine system, this technology is set to be integrated into a demonstration vehicle and tested in real conditions at the end of 2018.

The Falcon project, which is due to end in 2020, offers Renault Trucks a new laboratory on wheels not only for assessing technology aimed at further reducing the fuel consumption of trailer trucks, but also in preparation for the requirements of future regulations, within the EU, on the CO2 emissions of heavy goods vehicles, together with the volumes, dimensions and tyres.